Kawasaki Trading (Thailand) Co., Ltd.

Kawasaki Trading (Thailand) Co., Ltd.

Booth No. D11

Country. Japan

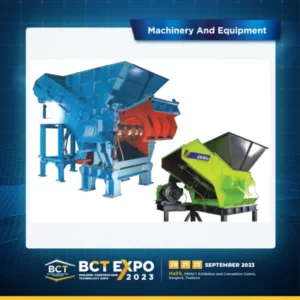

Profile. Machinery and Equipment

EARTHTECHNICA is a comprehensive crushing and crushing equipment manufacturer that was born in April 2003 by integrating Kawasaki Heavy Industries, Kobe Steel’s crushing and crushing technology, and sales force. We have a track record of supplying many crushing and grinding equipment including Primary Gyratory, Cone, Jaw, Impact crushers, Vertical Roller Mills, to a global market for mining, cement and construction industries. We are proud of the top share in the domestic crusher field, and in the environmental field, we are the first in the industry to commercialize our unique waste paper and plastic recycling plant, soil purification treatment equipment, etc. by making full use of elemental technologies such as crushing, sorting and solidification. In the powder processing field, we have a track record of supplying many powder and granular material processing plants including toner production plant, and recently we have continued to deliver to industries of pharmaceuticals and various battery materials (lithium ion, nickel-metal hydride). We are working to develop an efficient system and expanding our product lineup that complies with related laws and regulations and contribute to a sustainable society.

Website : https://www.earthtechnica.co.jp/english/

product 1

1.High Crushing Capacity

2.High Set Under Ratio and good product shape

3.Lower Energy Cost

4.Easy adjustment of discharge setting

5.Easy and Safety Maintenance

6.New Automation System

Product 2

1.Easy adjustment setting work

2.Simple and tough body structure

3.Large capacity

Product 3

1.Increased capacity with the new fixed blade (Continuous Line Cutting Design)

2.Easy to maintain; the rotating blades and fixed blades can be replaced from the outsid

3.The optimum blades can be selected from a wide variety of rotating blades, such as single blades and double blades or the like, depending on the raw material.

4.Serialized from the small machine “Multirotor ZERO” to Japan’s largest, ultra-large machine.

5.Unique pusher with optimized crushing efficiency, and rotor control.

6.Adopts a polygonal rotor to avoid the risk of raw material melting, and the like.

7.Foreign material handling is also possible (optional).