Comacchio S.p.A.

Comacchio S.p.A.

Booth No. F10

Country. Italy

Profile. Efficient Construction Technology and Smart Facility Management

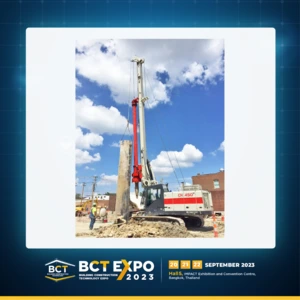

Wide range – 80 models from 2 to 68 tons for small, medium, and large diameter drilling Customization – designed to meet customers’ needs, developed in collaboration with the customer. Crawler units, truck mounter rigs, excavator attachments. Wide range of applications in the field of ground engineering, geotechnics, mining exploration, water well, and geothermal.

Website: www.comacchio.com

Social Media

Facebook: https://www.facebook.com/comacchiodrilling/

LinkedIn: https://www.linkedin.com/company/comacchio-drilling-high-tech/

The CH 450 is the winning solution for job sites of short duration that require frequent operations of transport, setting up and dismantling. Truly self-erecting. The machine is entirely autonomous and self-erecting, and can be transported in one piece/fully assembled with the rotary head and kelly bar installed. Once on site, the machine is easily off loaded from the truck and set up without the need for crane service. Wide range of drilling technologies. The CH 450 can be offered in CPD (cylinder pulldown) and WPD (winch pulldown) configuration. The innovative rotary head design adopted by Comacchio allows for the use of Kelly bars of various diameters, including HD (heavy duty) bars and XHD (extra heavy duty) bars, up to a maximum length of 14 m, with minor changes on the rotary head.

Comacchio offers a wide range of jet grouting drill rigs that can be configured for low-headroom operation or for single pass treatment depths in excess of 30 m with the use of telescopic mast extensions. Depending on the application and types of soils, three types of Jet grouting are normally used:

- Single Fluid Jet Grouting: Only grout is used to simultaneously erode and cement the soil.

- Double Fluid Jet Grouting: Grout is used with a coaxial jet of compressed air to increase the effectiveness of the erosive action and to obtain larger diameters.

Triple Fluid Jet Grouting: The erosive action is given by one or more jets of water and compressed air, where the cementation is delivered by grout injected through one or more nozzles placed below the air/water nozzle(s), thus obtaining larger columns even in cohesive soils.

The Comacchio GEO line drill rigs are designed as multipurpose units for carrying out destructive and non-destructive rotary core drilling, the collection of disturbed and undisturbed samples, in situ testing (SPT), installation of piezometers, inclinometers, and other geotechnical instrumentation. In addition to geotechnical investigations in the strict sense, the drilling rigs of the GEO line successfully operate in a constantly expanding sector such as environmental monitoring. The Comacchio drilling rigs of the CA series are designed and built to meet the needs of drilling contractors that specialize in the construction of small and large water wells. The range of uses of these machines include installation of piezometers and groundwater monitoring wells, construction of wells for public, agriculture, commercial, industrial, and domestic water supply, along with well repairs and deepening.